Get In Touch

Office Address

“Vit Bhavan”, Opp. Gurukul Temple,

Near Ankur Complex, Behind ICICI Bank,

Gondal Road, Rajkot – 360002, Gujarat, India.

Factory Address

Mahavir Ind. Estate, Survey No.4/5/6/18 NH. 8B Gondal Highway, Veraval, Shaper. Rajkot-360024, Gujarat, India.

Call us

+91 9925100979

+91 2827252403

Mail us

info@kasumabearings.com

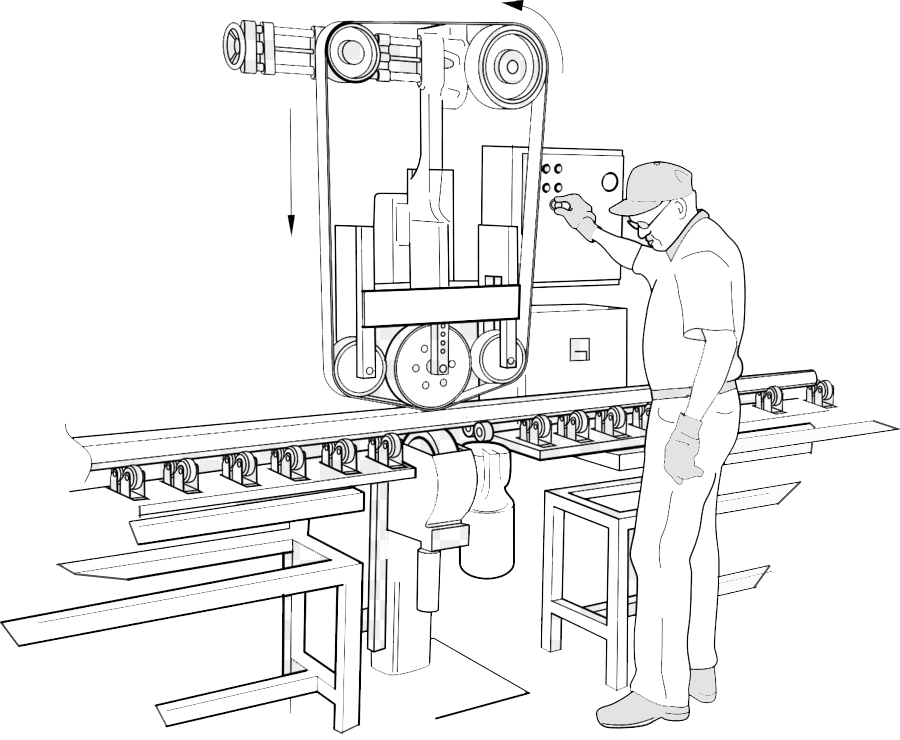

Manufacturing Process

Prefabricate

"Beyond a Process, There lies aSuccess "

With a reputation built on the rapid and professional responses that span over 40 years in the bearing business, Kasuma Bearings is among the finest manufactures of precision-machined bearings available to date. We utilize top-quality materials to create top-notch products that stem from our leading-edge technological expertise. And with expert mechanical engineers, leveraging years of experience in bearing scores of innovative designs, we build a custom solution that perfectly meets your application needs. The result-Get delivered the best.

And for all you know, with years of history, manufacturing quality bearings has given us the knowledge and expertise to service any of your bearing modification or manufacturing needs. With all this and more, we've perfected our Manufacturing Process to provide you with unparalleled products. Needless to say, today, we are known equally for our quality and value.

Such extensive treatment goes behind the making of every bearing. With 100% online inspection and an automatic production line, we are capacitated to produce approx. 6 million bearings a year. We have a range of caged bearings consisting of Steel / Brass / Teflon / Aluminum Cage depending upon applications and the customer requirements.

Manufacturing Process

Induction Forging

Spheroidised Annealing

CNC Pre-Machining

Heat Treatment: Bearing Rings & Rollers are heat treated and tempered within 59 to 63 HRC

Grinding: With In-Process Gauges

Super Finish of Rings & Rollers

Assembly : Rollers sorted with automatic sorting machine

Laser Marking

Washing & Oiling

Grease Filling

Packing

Dispatching

The Raw Materials We Use

Quality

"Beyond a Process, There lies aSuccess "

With a strong belief of "there is no alternative to quality", Kasuma Bearings uses the most updated measurement and testing technology to enforce rigorous quality checks on all its products. Precisely why, you can be rest assured to get only the best. Having said that, we make sure that all the processes are carried out as per the Process Control Plan. And with specific work instructions given to all regularly trained employees, we ensure that they give their commitment in everything they do and live by the high-quality standards that we have set over the years.

We have also incorporated innovative engineering technologies that ensure high-quality performance in the manufacturing of advanced system bearings. The production capacity of our company is approx. 6 million bearings annually, and to ensure the long life of the bearing we have installed In-House quality control systems like:

Metallurgical Laboratory

Hardness Tester

Profile projector for testing micro geometry at turning stage

Surface Finish Tester, etc

Metallurgical Microscope

- Spheroidize structure

- Amount of perlite

- Micro inclusions

- Carbide network

- Carbide Streaks (bending)

We have the latest technology machine to monitor Bearing Noise Level and Life Testing Machine (Endurance Test) that monitors vibrations, temperature, and speed of bearing under test. In order to develop the business, today, we have established our own R&D Department for designing of product and all activities are carried out by our design experts using latest designing software.

We focus on rapidly evolving in all our endeavors. That is why; we have continuously introduced new trends in the market, with the latest technology, style, and ultra-modern facilities while creating economical as well as world-class products.

We at Kasuma carry inspection checks to bearings and components, on the grounds of:

• Eccentricity

• Parallelism

• Roundness

• Squareness

• Concentricity

• Coaxially

• 3-point

• Blue Contact

• Residual Magnetism